Heat Sink Effect In Welding

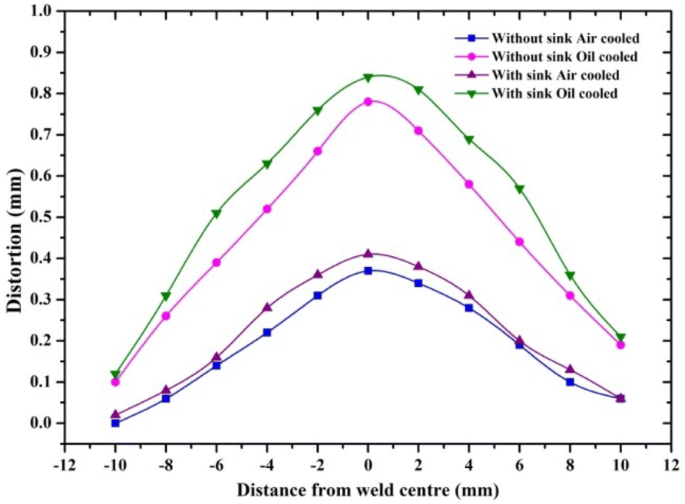

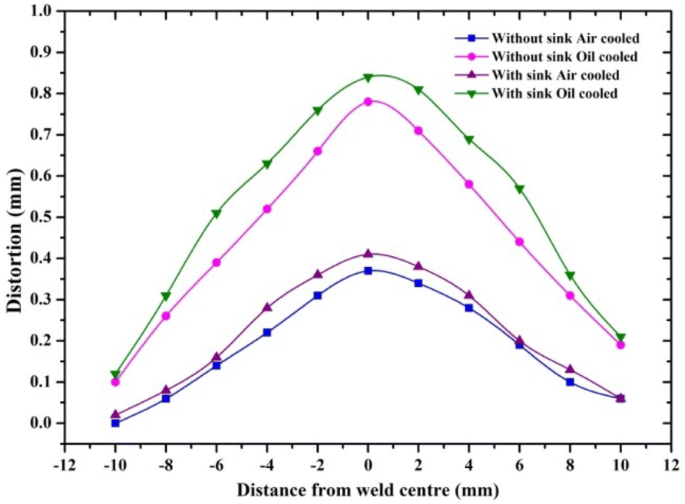

The thing to bear in mind the AL heat sink will do just that suck all the heat into it. Residual stress and out-plane distortion decrease with cooling intensity increase.

What Are Heat Sinks How Heat Sinks Work Popular Types Arrow Com

A heat sink also commonly spelled heatsink is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium often air or a liquid coolant where it is dissipated away from the device thereby allowing regulation of the devices temperature.

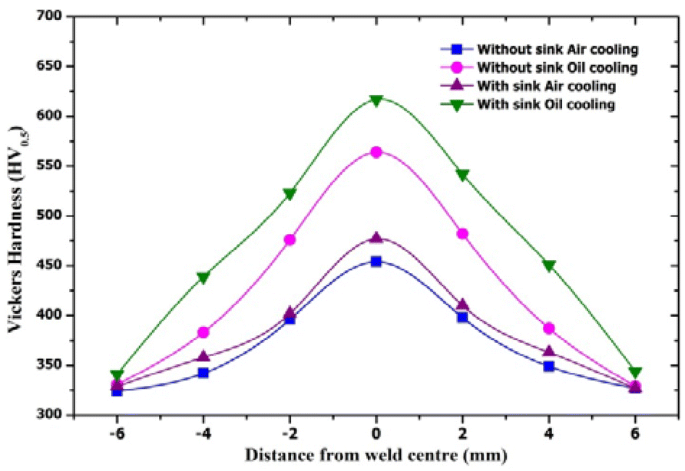

Heat sink effect in welding. So be prepared it will get HOT to your arms and hands. Factors such as thickness thermal conductivity heat treatable and non-heat treatable alloys multi-pass welding and heat-sink compounds also have an effect on the width of the HAZ. Mechanical behaviors of pulsed laser welding with heat sink in C-276 are analyzed.

Weld geometry affects the heat sink. A basic two-dimensional model was created to represent the net heat sink effect of surplus material using Duhamels theorem to superpose the effects of an infinite number of line heat sinks of. After the heat sink is applied the peak of longitudinal stress is decreased to around 290 MPa.

Heat energy is lost from the weld primarily via conduction of heat by adjoining material and by the electrodes themselves which can act as heat sinks. VPPA process An investigation into the heat sink effects due to weldment irregularities and fixtures used in the variable polarity plasma arc VPPA process was conducted. Up to 10 cash back The effect of forced cooling using heat sinks on the mechanical properties and interpass waiting time of two-pass welds has been studied for a martensitic steel with a yield strength of 960 MPa when the interpass temperature was 100 C.

Minimizing the heat input with the use of an automatic process mode is very beneficial. Any change in volume of material available to act as heat sink will affect the weld. After the heat sink is applied transverse stress in the weld zone is decreased slightly.

Chart of the weight. In computers heat sinks are used to cool CPUs GPUs and some chipsets and RAM modules. No more short sleeve welding with an AL block.

An increase on tensile strength about 58 and ductility close to 29 for welds performed in partial aging materials with respect to the welds with artificial aging condition 6061-T6 alloy was also observed. The temperatures during cutting. At the case without heat sink a maximum of the longitudinal stress 360 MPa is generated in the weld metal.

Copper is probably the best material for this. It gives a path of least resistance to any excess heat that is applied to the soldering joint. Use a heat sink whenever possible.

Transient stress valley is produced due to temperature valley formed by heat sink. Then it is decreased away from the weld metal. The heat transfers through this chunk of metal instead of the workpiece.

The long term goal of this modeling is to provide means for assessing potential heat sink effects and eventually to provide indications as to changes in the welding process that could be used to. In a similar way the heat-affected zone for high-temperature cutting operations are also influenced by. It discolors less and warps less and that my friend is big big deal because if you have welded much stainless at all you know that it tends to warp a lotand if it overheats too much stainless steel can lose its corrosion resistant properties.

This video shows four different welding or brazing tables. Heat sink is good for pulsed laser welding since it needs smaller. Emphasis is on using a eat Sink to minimize warping of the steel table top.

When you have a heat sink stainless steel welds better and faster. Heat sink effects on weld bead. Up to 10 cash back The over-aging of the heat affected zone tends to diminish when the heat sink is used as compared with the reference welding condition.

Function of heat loss from the weld area. Faster welding speed will reduce the HAZ area. The heat affected zone HAZ is a non-melted area of metal that has undergone changes in material properties as a result of being exposed to high temperatures.

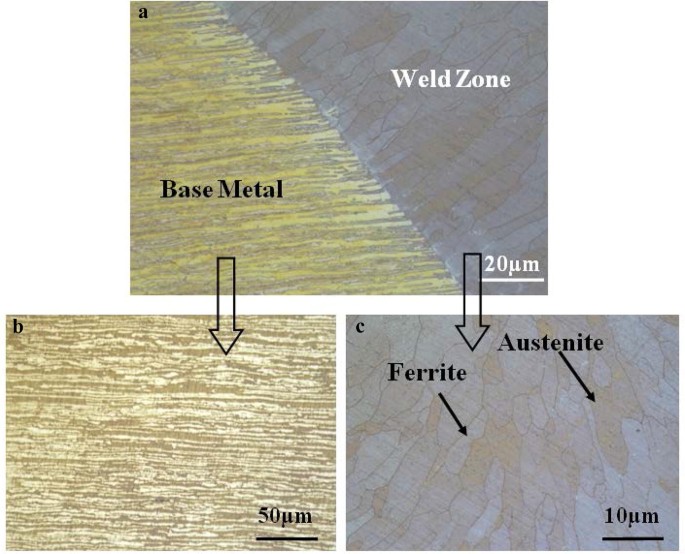

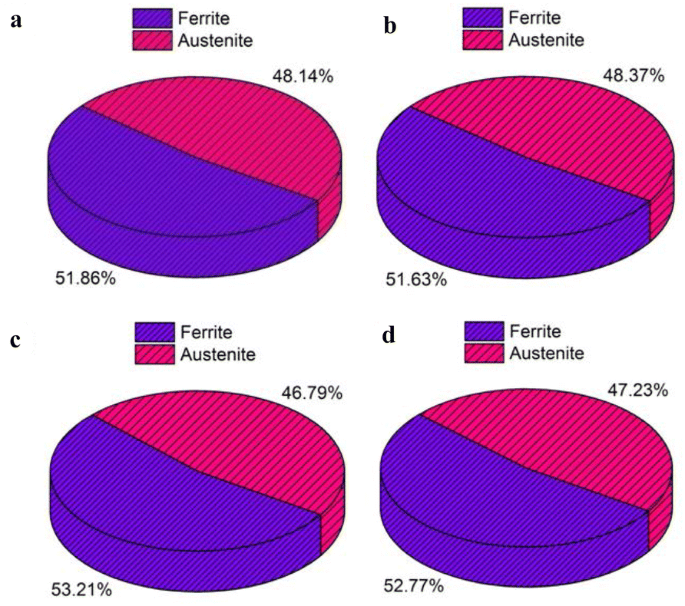

The application of a heat-sink compound provides a reduced width of the HAZ. The aluminium heat sink is a good conductor of heat and thus has a higher cooling rate than air but less than that of oil. Cross-weld tensile and 40 C Charpy-V impact toughness properties were examined.

Heat sinks are usually made of a low-mass metal with a high heat conductivity like aluminum. Instead of traveling down the wire or lead any extra heat will travel into the heat sink and be mitigated. Adding large metal blocks near the weld on both sides will reduce the amount of distortion because it will act as a heat sink by pulling heat from the weld and redistribute it in the parent material allowing for even cool down.

I have a 38 welding table of AL and while it has some great uses I often forget Im using it versus my steel table and have the blisters to prove it. A smaller heat sink leads to slower cooling means larger HAZ. The HAZ is the area between the weld or cut and the base unaffected parent metal.

A chunk of aluminum copper or brass works well as these metals tend to suck out heat better than steel. The heat sink can double as a backing bar in some cases. Speed of cutting operation.

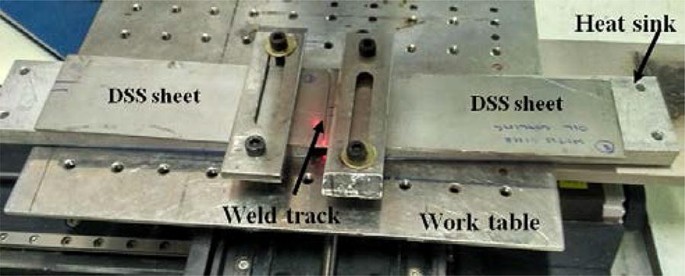

These changes in material property are usually as a result of welding or high-heat cutting. Heat sink effects in VPPA welding The development of a model for prediction of heat sink effects associated with the Variable Polarity Plasma Arc VPPA Welding Process is discussed. The aluminium heat sink conducts the heat developed during welding and thus takes away the heat quickly from the specimen.

Transverse shrinkage distortion increases with cooling intensity increase.

Effect Of Heat Sink And Cooling Mediums On Ferrite Austenite Ratio And Distortion In Laser Welding Of Duplex Stainless Steel 2205 Springerlink

What Are Heat Sinks How Heat Sinks Work Popular Types Arrow Com

Effect Of Heat Sink And Cooling Mediums On Ferrite Austenite Ratio And Distortion In Laser Welding Of Duplex Stainless Steel 2205 Springerlink

Aluminum Heat Sink China Aluminum Heat Sink Heatsink Cool Pc Aluminum Extrusion

Pure Copper Skived Fin And Cnc Processing Heat Sinks Lr0115 Pure Copper Copper Sink Heatsink

The Position Of The Heat Sink In The Welding Process Download Scientific Diagram

401f Ssr 500 600a Module 200 350a Shape Code And Overall Dimensions Of Module Shape Coding Dimensions Shapes

Heat Sink Thermal Resistance And Size Calculation Heat Sink Selection

The Position Of The Heat Sink In The Welding Process Download Scientific Diagram

Applications Of The Heat Sink Radiator Huimultd Heatsink Heat Thermal Grease

Effect Of Heat Sink And Cooling Mediums On Ferrite Austenite Ratio And Distortion In Laser Welding Of Duplex Stainless Steel 2205 Springerlink

Https Www Mdpi Com 2227 9717 9 5 847 Pdf

Effect Of Heat Sink And Cooling Mediums On Ferrite Austenite Ratio And Distortion In Laser Welding Of Duplex Stainless Steel 2205 Springerlink

Effect Of Heat Sink And Cooling Mediums On Ferrite Austenite Ratio And Distortion In Laser Welding Of Duplex Stainless Steel 2205 Springerlink

Heat Sink Seminar Topics Mechanical Engineering Seminar Topics

Heat Sink Mg L Diagram Heatsink Relay Heat

A Numerical And Experimental Investigation Of Heat Transfer And Fluid Flow Characteristics Of An Air Cooled Oblique Finned Heat Sink Sciencedirect

Posting Komentar untuk "Heat Sink Effect In Welding"